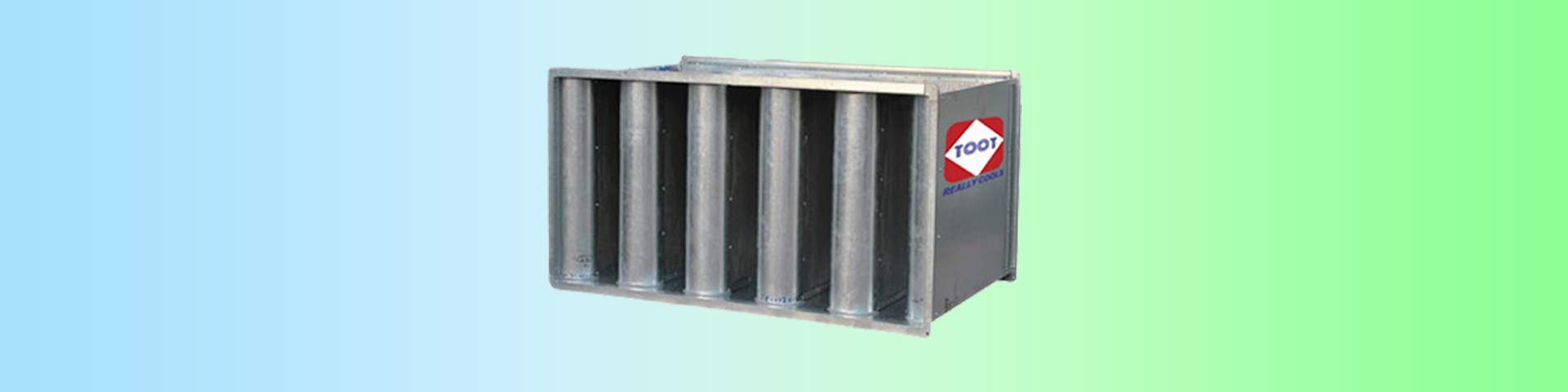

Sound Attenuators

Toot Sound Attenuators are designed and manufactured to the Standards complying for ASTM E336 -20 test

These Units are designed with parameters such as insertion loss, air-regenerated noise, and pressure loss as per the customer requirement. Accordingly, the density of the Sound absorbing material and splitter are selected and manufactured.

Salient Features

- Casing Construction material thickness varies from 0.6mm to 1.2mm using Stainless Steel 304, 316, and GI Sheets also

- Rock Wool and Glass wool are mostly used as sound absorbents

- SS Rivet is used for longer casing life

- Multiple modules construction as per the site condition can be manufactured

- "L" angles are used for mouth connections

- The sealant is applied at the mating parts to avoid air leakage

- SS & GI Perforated sheets are used for construction

- Baffle / Nose design can either round or triangular

- Our Attenuators can withstand Fire test at 200 degrees centigrade for an hour